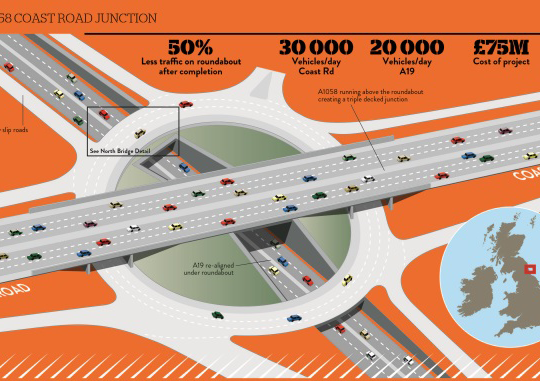

Project Description

The Silverlink Interchange to the east of Newcastle city centre receives around 50,000 vehicles every day, with approximately 30,000 travelling above it from east to west along the A1058 Coast Road and another 20,000 vehicles going directly around it on the A19 from north to south. To alleviate the congestion caused by the volume of traffic travelling across the roundabout, Highways England appointed WSP to redesign the junction. The resulting plan re-routes the A19 through a cutting running beneath the roundabout, with new slip roads constructed to allow access to the lowered section and so reducing usage of the roundabout by approximately 50%. In addition, a new single span structure was built to carry the A1058 over the cutting in the centre of the roundabout, plus a further two single span structures to take the roundabout across the new underpass, and voila the North East’s first triple decker junction is born!

The Challenge

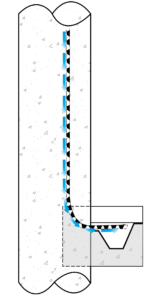

In total the new underpass cutting is about 1km long, with the depth from the roadway to the roundabout averaging between 5 to 7m, rising to 15m in the central section. To form the retaining walls for the dive under, 583 contiguous piles were installed by Bauer Technologies. The largest piles, up to 1.5m in diameter, also act as structural supports for the A1058 flyover above the cutting. The bored contiguous piles constructed to form the retaining walls are up to 30m deep to enable the lowered section of A19 to be excavated. Without an adequate back of wall drainage system, the gaps between each pile provide an uncontrolled pathway for groundwater to escape. This results in the erosion of fines and pockets of localised water pressure that are detrimental to the stability of the supporting structure.

The Solution

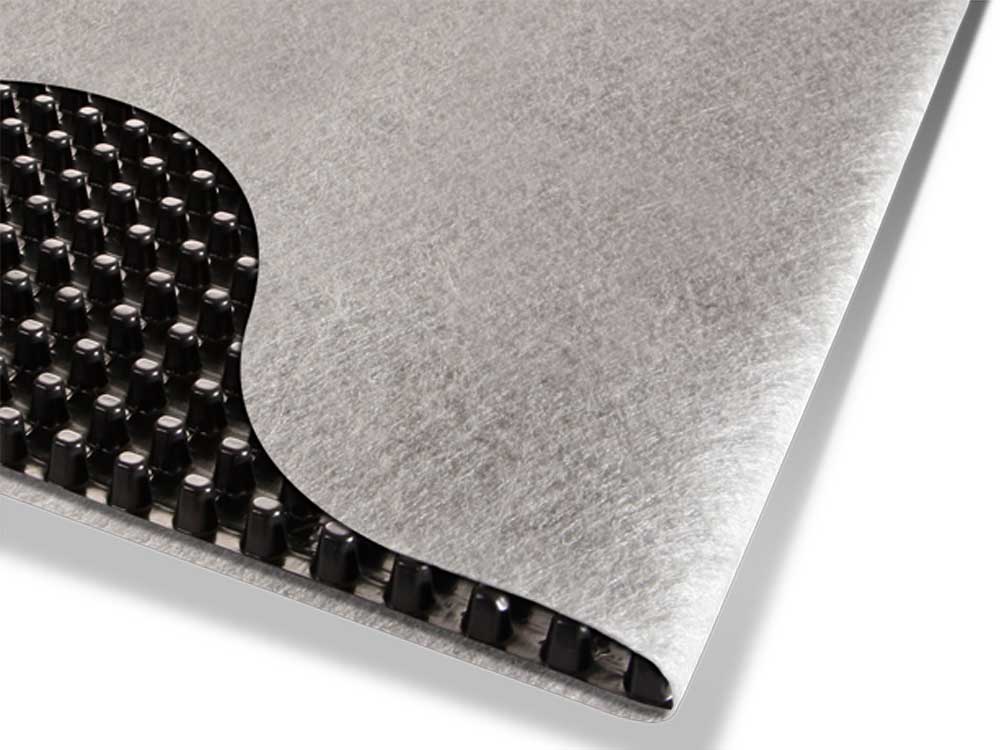

In order to stabilise the retained earth behind the underpass wall, ABG Piledrain was specified to alleviate ground water pressure. A 1.1m wide geocomposite was supplied (also available in 275mm and 550mm widths) comprising an impermeable single cuspated HDPE core, with a non-woven geotextile wrap covering the front face and bonded to the edges at the back.

The front face of the drainage gecomposite is completely covered by the geotextile layer, and this side is pressed against the compacted earth in order to filter water through it and prevent erosion of the soils. The ground water filters through the geotextile into the cuspated drainage core, with a 0.99 l/s in-plane flow capacity providing efficient drainage down to a drainage channel at the base of the structure. The drain’s flow rate is tested at 200 kPa confining pressure to simulate conditions when compressed into position against the soil. The back of the Piledrain is impermeable, ensuring that water filtered into the drain does not leak through to the face of the wall.

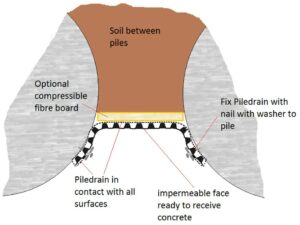

The ABG Piledrain is fixed into position to the sides of each contiguous pile using masonry nails and plastic washers at 0.5m centres. The drains are fixed to each pile down to ground level and terminated above a drainage channel cast into a concrete plinth at the base. The geocomposite is kept in close contact with both adjoining piles and the soil, fitted in a “U” shape to span the gaps (see illustration detail below). A sprayed concrete finish adheres well to the pocketed side of Piledrain.

Cross section to show the flexible Piledrain material conforming to the gap in between piles and example of termination into drainage channel

The ABG Service

In total 3,000 linear metres of geocomposite drain (supplied in 50m long roll lengths) were installed to fit the gaps in between the contiguous piles, with specification detail and installation assistance provided during the design and construction phases.

Contact ABG today to discuss your project specific requirements and discover how ABG past experience and innovative products can help.