Project Description

Doune Castle is a medieval stronghold located in the Stirling district of central Scotland that originally dates back to the thirteenth century. The castle is sited on a wooded bend where the Ardoch Burn flows into the River Teith. Upstream, 8 miles to the northwest, lies the edge of the Trossachs and the beginning of the Scottish Highlands. Doune Castle was used as a filming location for the Winterfell Kingdom in the Game of Thrones TV series and as the backdrop for various scenes throughout the Monty Python and the Holy Grail movie.

The Challenge

Client Historic Environment Scotland were undertaking a maintenance programme to upgrade the path network surrounding the castle, including a new stepped ramp from the main entrance road up to the Doune village footpath. The change in elevation from the road to the top of the footpath required a new retaining wall to secure the cut slope. The contours of the slope meant a stone or gabion solution would require a greater footprint, with the toe of the wall extending out onto the access road. The Estate Manager was also looking for a solution that would blend in with the woodland surroundings and minimise the number of carbon intensive deliveries associated with using hard landscaping materials.

The Solution

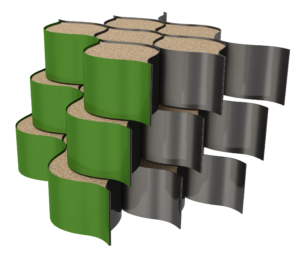

A vegetated Webwall design was selected. The flexible HPDE geocellular panels are a natural green colour at the front cells and the panels are supplied in flat coils for convenient handling. The panels are easy to unfold, expand and pin into position to suit the curved footprint of the site, with the widest Type C Webwall panels (4m long x 2m deep x 0.25m high when expanded) used at the base of the wall. The first layer of panels were stretched out and pinned into position onto a stable, excavated footing before backfilling with site won fill.

The fill is compacted and the process is repeated until the full height of the wall has been achieved. The individual cells of the Webwall panels provide cohesion to marginal soils, avoiding the need to import additional drainage stone and topsoil. Parts of the wall exceed 1.5m in height, and for these sections layers of Abgrid geogrid are installed to provide additional reinforcement to the build-up. ABG’s Fildrain 7DW/NW8 gecomposite is also installed at 1m intervals to provide drainage at the back of the wall. The wall is designed to a 55° slope angle and uses Type B Webwall panels in the middle section (4m long x 1.5m deep x 0.25m high) to create the required elevation. Type A panels (1m deep) are used for the top section as the wall steps back to meet the crest of the slope. The easy to handle and flexible nature of the Webwall panels enables a fast installation, completed in just 4 days compared to the time and cost (from both a financial and carbon point of view) required to build an equivalent stone structure.

The ABG Service

Indemnified design with slope stability calculations to suit the soil properties. The construction of the wall was supervised by ABG’s installation partners Geogreen.