Project Description

The Highways Agency commissioned the improvement of the A1 between Dishforth to Leeming. The road is an all purpose, two lane carriageway carrying in the region of 50,000 vehicles per day. Constructed in the early 1960’s the route failed to meet current alignment standards and had a number of non-standard access junctions. The route had a poor safety, congestion and journey time record.

A joint venture between Carillion and Morgan Sindall carried out the 12 mile (19.3km) upgrade.

The Challenge

Highway drainage represents a significant part of any scheme, including edge of carriageway drainage which protects the sub-base from water damage. This is normally achieved using a stone filled trench which means importing large quantities of carbon intensive drainage stone from distant quarries. Achieving this on a live, restricted main carriageway is problematic from a safety and ecological point of view. Any method which reduces the use of imported granular material, along with reduced excavation and disturbance of the carriageway shoulder is welcome.

The Solution

The contractor proposed a findrain Type 6 from the Highways Construction Details drawing number F18 and Specification for Highways Works Clause 514 with Appendix 5/4.

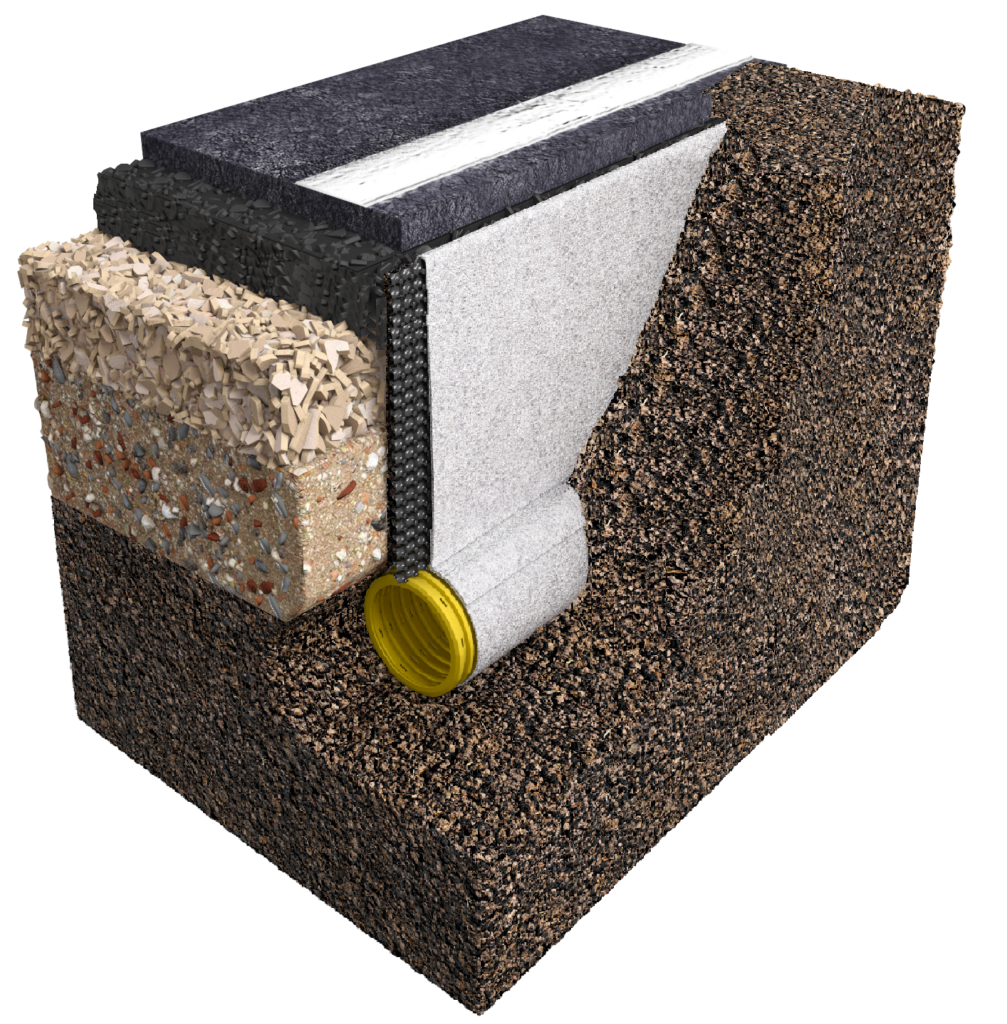

The contractor chose the now BBA certified ABG Fildrain Type 6 as a suitable findrain, saving 4,000 tonnes compared to the crushed stone option. ABG Fildrain Type 6 provides vertical drainage on both sides, whilst acting as a barrier and protecting the sub-base from inundation from the verge. It is a double cuspated drainage geocomposite, fully wrapped with a filter geotextile with an integral pipe sleeve. The unit is laid alongside the trench, threaded with a perforated pipe and dropped into a narrow trench before backfilling by pushing and compacting the excavated soil back into the trench adjacent to the drain. The surface is then covered with soil or a shallow apron of stone.

The ABG Service

Assistance with cost comparisons and provision of a staged delivery to suit this narrow corridor site. Supplied relevant documentation to assist with approvals.

Contact ABG today to discuss your project specific requirements and discover how ABG past experience and innovative products can help.

This scheme is an example of implementing an idea from the Highways England “Managing Down Costs” Toolkit.