Introduction

The function of a geotextile filter is to allow water to enter a drainage media (such as gravel or a geosynthetic) while preventing soil particles from doing so. Whether using drainage stone or a pre-formed polymer drainage core, a geotextile filter is required in order to provide drainage performance for the lifetime of the project. This technical note discusses key properties of filtration geotextiles and how they function.

Pore Size

All soils have a range of particle sizes and the distribution of these particle sizes can be obtained in a soils laboratory.

In a similar manner, a non-woven geotextile has a gradation of pores (holes, or gaps) within its structure and an ‘O90’ value can be measured. The O90 of a geotextile filter means that 90% of the pores within the geotextile are smaller than the O90 value. For example, the O90 may be 120 microns (i.e. 0.12mm) which means that 90% of the pores are 0.12mm or smaller. Silty sand, for example may have particles from 2mm to 2 micron in size. This means that some of the soil particles are smaller than the geotextile pores and so will pass through the geotextile, whilst others will be retained.

A geotextile can be designed to match a particular soil but this is often not necessary as non-woven geotextiles are manufactured as standard to be compatible with the majority of soils. However, there are difficult soils and complex applications which are discussed in a later section. Note that the pore size should be specified as a range or a maximum value.

Permeability

The permeability of a geotextile must be greater than that of the adjacent soil. This means that the flow rate of water through the geotextile is greater than that of the water flow rate in the soil so that the geotextile does not become a pinch point for the movement of water from the soil into the drainage media. The permeability of soil may be 1 x 10-8 m/s or lower for a cohesive soil, or up to 1 x 10-4 m/s for sand.

A typical non-woven geotextile will have a perpendicular water flow of around 100 l/m2·s at a 50mm hydraulic head which is at least 1,000 times more than that in typical soils.

Therefore in most situations, the factor of safety for permeability is very high, even allowing for some minor reduction in the flow performance of the geotextile over time.

Figure 1: ABG Terrex SNW a typical non-woven filtration geotextile

Break Through Head

Some geotextiles exhibit a surface tension effect which prevents water from entering the geotextile until sufficient pressure head is achieved. For some geotextiles, this pressure head is 25-40mm which is one reason why the geotextile permeability and water flow is tested at a 50mm head. None of this is an issue for geotextiles used in relatively deep installations, however in shallower applications and/or when water infiltration is required (such as in a soakaway), this can be problematic. This is why ABG only uses geotextiles with zero breakthrough head for all applications.

How a Non-Woven Geotextile Filter is Formed

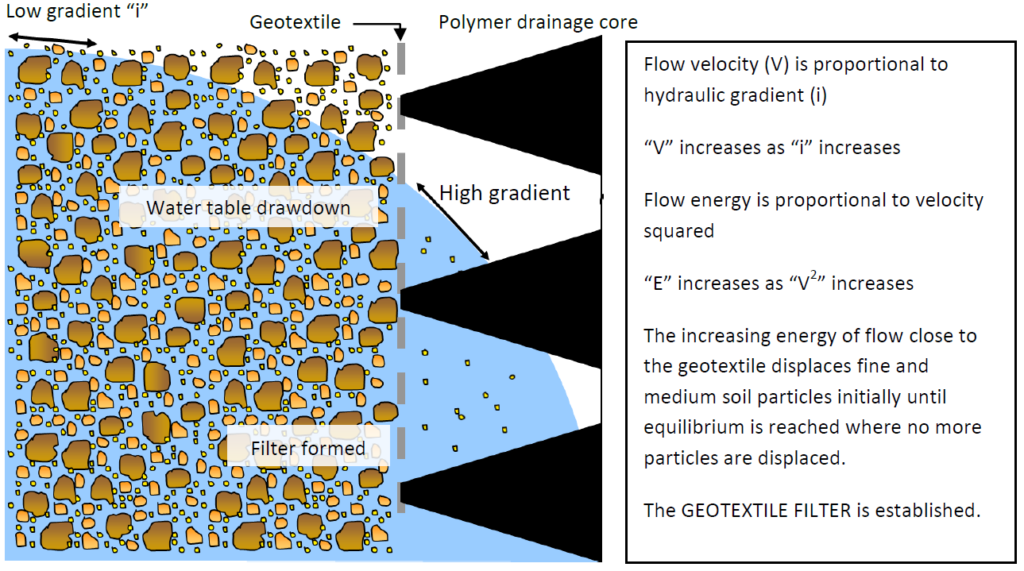

A correctly designed geotextile matched to the soil grading will allow some soil particles to pass through the geotextile. In this way, the geotextile creates a filter zone within the soil adjacent to the geotextile, as shown in Figure 1. The relatively high energy water close to the geotextile forces the fine and medium size particles through the geotextile (this explains the slight discolouration of the water in the first 3 – 4 weeks). Slightly further away the water has less energy and can only move the fine particles. Further away again and the soil is undisturbed. What remains is a graded filter zone in the soil with coarse, then coarse and medium, and finally coarse, medium and fine particles.

Figure 2: Geotextile filter process

Do Geotextile Filters Clog?

All filters clog to a certain extent, whether geotextile or any other material (e.g. stone). However, as noted earlier filter geotextiles are far more permeable than soil – allowing at least 1,000 times more water flow than typical soils. Even if a geotextile loses 99% of its flow capacity, it will still provide adequate flow. So rather than asking ‘will it eventually clog?’ a more perceptive question is ‘will it excessively clog?’ The answer to that question depends on the site conditions.

Common Conditions

In common conditions, good quality filter geotextiles will not excessively clog. Common conditions are where the soil and water conditions do not fall into any of the categories below. This is backed up by numerous case studies and laboratory experiments such as (Fannin, 2010; Giroud, Luettich, Richardson & Zhao, 2002; Koerner, 2012). A good quality filter geotextile is one that complies with BS 8661:2019.

Uncommon Conditions

Experience shows that the following conditions give rise to concerns about geotextile filter applications and indeed also cause problems for traditional filter stone (Koerner, 2012):

- Poorly graded (i.e., all soil particles are approximately the same size) fine, cohesionless soils such as loess, rock flour, PFA and stone quarry fines.

- Dispersive clays that separate into individual fine particles over time (most clays do not do this).

- Cohesionless soils with irregular (gap-graded) particle size distributions, coupled with high energy water flows.

- Highly alkaline groundwater where the slowing of the liquid as it flows through the geotextile can cause calcium, sodium or magnesium precipitates to be deposited.

- Liquids with high volumes of suspended solids such as turbid river water or dredged water, or coupled with high-microorganism content, as in bioreactor filter beds, old mine workings discharging orange ochre and agricultural wastes.

- Situations relating to high energy water and or reversible water flows such as tidal zones or coastal applications.

In these situations specialist advice should be obtained regarding the most suitable option for providing filtration. In most of these situations the selection of specialist geotextiles will provide good filtration performance. In other situations the geotextile may clog resulting in a reduced life expectancy of the geotextile and frequent replacement will be necessary.

Conclusion

In common soil conditions, good quality filter geotextiles selected in accordance with BS 8661:2019 will maintain good long term filtration performance. In uncommon conditions (such as those outlined above) specialist advice should be obtained regarding the most suitable option for providing filtration.

References

British Standards Institution (2019) Geotextiles – Guidance for specification for basic separation and filtration. BS 8661:2019.

Fannin, R. J. (2010). On the clogging of geotextiles. In 9th International Conference on Geosynthetics. Guaruja, Brazil.

Giroud, J., Luettich, S., Richardson, G., & Zhao, A. (2002). Permeability of geotextile and granular filters. In 7th International Conference on Geosynthetics. Nice, France.

Giroud, J. (2010). Development of criteria for geotextile and granular filters. In 9th International Conference on Geosynthetics. Guaruja, Brazil.

Heibaum, M. (2014). Rethinking geotextile filter design. In 10th International Conference on Geosynthetics. Berlin, Germany.

Koerner, R. (2012). Designing with geosynthetics. Xlibris Corp