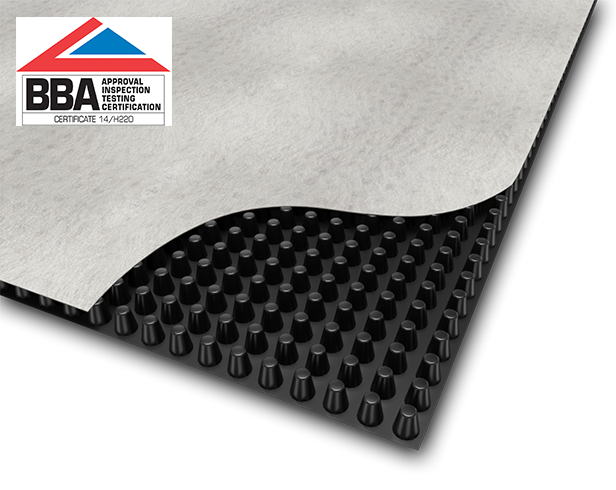

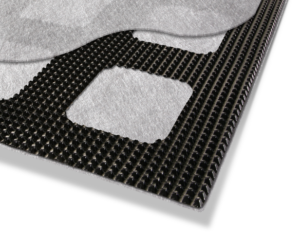

ABG Deckdrain is used in civil engineering and construction drainage applications; including bridge abutments, buried structures, retaining walls, tunnels, roof gardens and covered potable water reservoirs. ABG Deckdrain geocomposite consists of a high strength, flexible polyethylene cuspated core with a non-woven filter geotextile bonded onto one or both sides. The geotextile filters a wide range of materials whilst allowing water to percolate into the core of the geocomposite before draining to a discharge point.

The HDPE cuspated core of the geocomposite provides a free flowing drainage void. The cusps are designed to support the geotextile which is bonded to the core, to ensure that it doesn’t deform into the drainage void under the pressure of the backfill material. ABG Deckdrain is designed to allow flow in all directions, unlike linear or pipe systems.

ABG Deckdrain is durable and sufficiently robust to resist the mechanical stresses imposed during installation and then on throughout its design life. Use of ABG Deckdrain eliminates the need for further protection of the waterproofing system. ABG Deckdrain has been creep tested at compressive loads of up to 1,000kPa to give a design life of 120 years.

ABG Deckdrain is a UK manufactured BBA certified product, with a long history of use on National Highways, Transport Scotland and other major Highways schemes. ABG Deckdrain is available in a range of flow capacities from 1 l/m/s to 95 l/m/s, corresponding to thicknesses ranging from 4mm to 50mm, and can be supplied in a variety of roll sizes designed to suit differing site requirements.

ABG Deckdrain geocomposite is used in the construction of green bridges and green tunnels to protect the waterproofing and provide drainage to the structure, which removes the need for bulky porous blocks and the logistical challenge of importing granular fill.

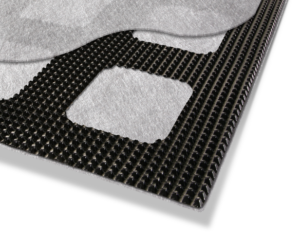

Deckdrain G for Leak Detection

The increasing demand for leak detection and location “intelligent membranes” requires a complementary drainage and protection layer. ABG Deckdrain G has been designed with a special latticed cuspate design, developed to support this technology and as implemented on a range of reservoirs across the UK. In addition to providing multi-directional flow, the Deckdrain G offers protection against puncture of the underside of the geomembrane layer. In the event of a tear to the membrane, the water has an easy drainage pathway to the sump so that the source of the leak can be identified and repaired.

Typical Client Profile

- Drainage Contractors

- Water Companies

- Covered Reservoir Engineers

- Tunnel Engineers

- Green Roof Consultants

- National Highways

- Structural Engineers

- Rail Engineers

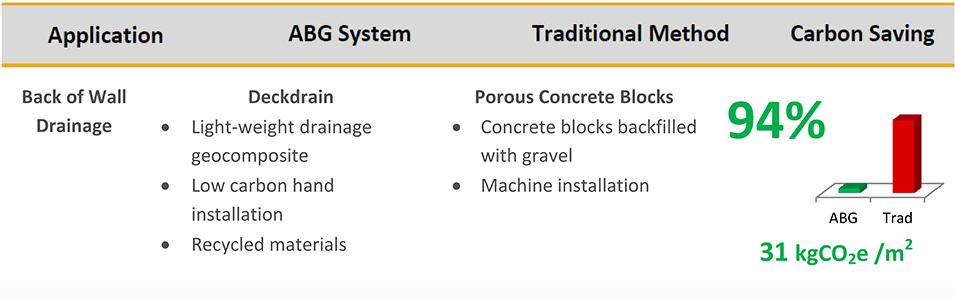

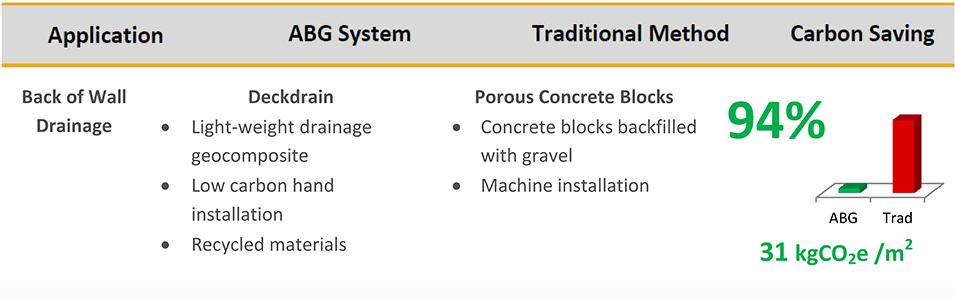

Back of Wall Drainage – Carbon Footprint Saving

The use of ABG Deckdrain Geocomposite can save up to 94% on carbon footprint compared with traditional porous concrete block drainage methods:

Click to read the full carbon footprint assessment.