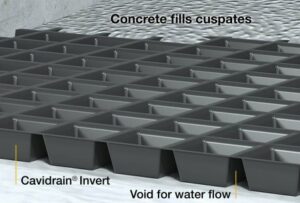

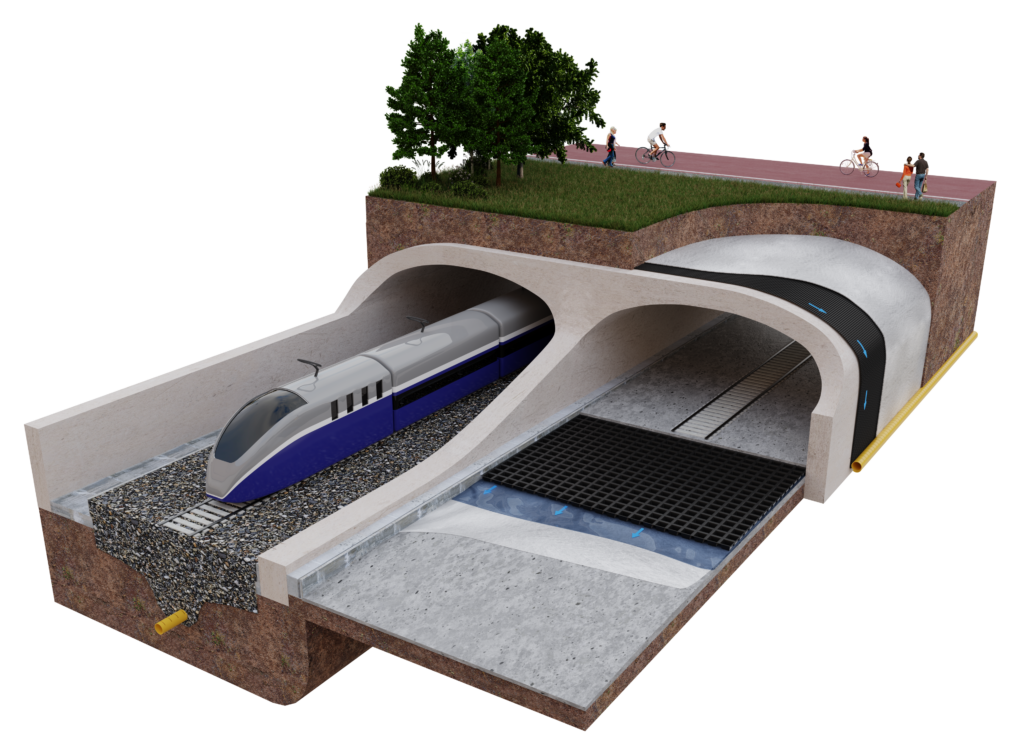

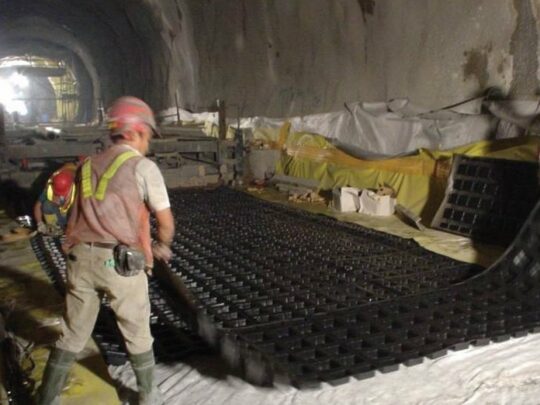

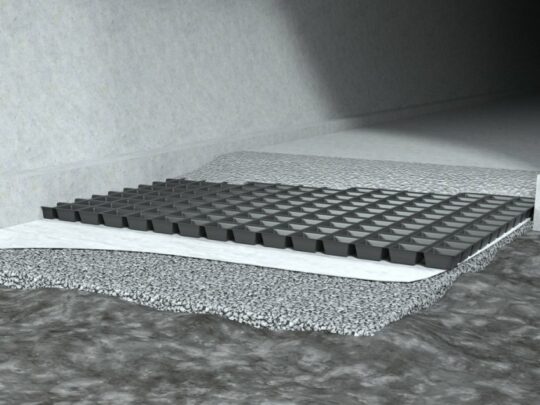

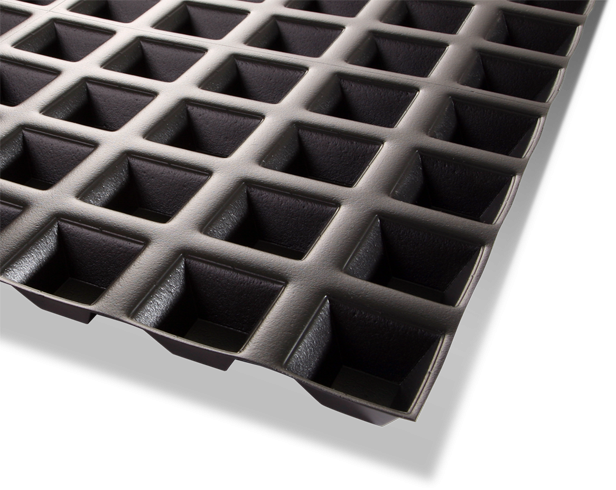

Cavidrain® Invert provides a pre-formed tunnel invert drainage layer into which the concrete floor slab can be easily cast. Cavidrain® Invert replaces the crushed stone and pipes traditionally used to collect and transport away infiltration water.

Cavidrain® Invert has been optimised for high in-plane flow to mitigate problems caused by mineral calcification.