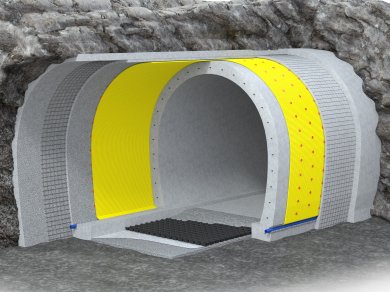

The Cavidrain® range is a pre-formed cavity drainage system designed to relieve the effects of water penetration from tunnels and is suitable for both remediation and new build. Cavidrain® can be used in both tunnel walls and tunnel invert drainage.

Cavidrain® has been engineered to provide a highly effective drainage system and mitigate the adverse effects of water on tunnel structures.

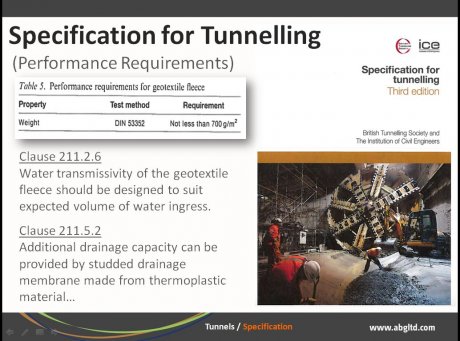

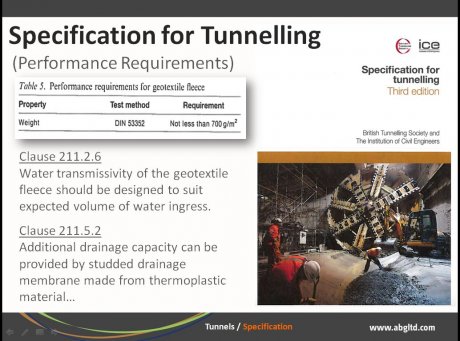

Extract from ABG’s Tunnel Drainage CPD. Click to register for the CPD.

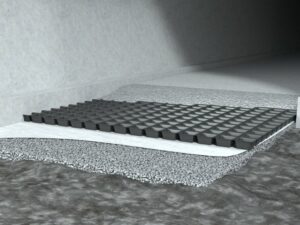

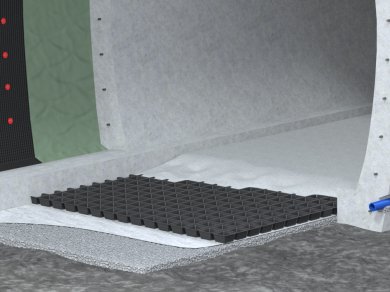

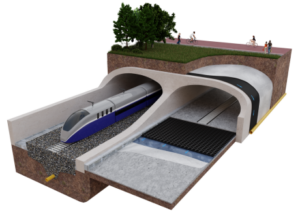

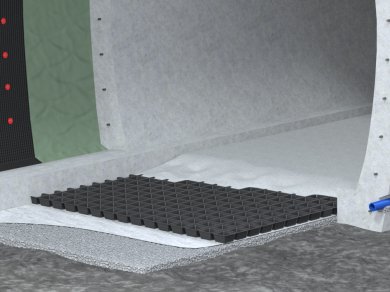

Tunnel Invert Drainage

Cavidrain® Invert provides a pre-formed drainage layer into which the concrete floor slab can be easily cast and at just 20, 40 or 60mm thick, replaces the crushed stone and pipes traditionally used to collect and transport away infiltration water.

Cavidrain® Invert is optimised for high in-plane flow velocity to mitigate problems caused by mineral calcification and is designed to achieve a maximum bearing area and withstand normal installation loadings. The final compressive load is taken by the concrete infill.

Cavidrain® Invert has been used successfully throughout the world in several prestigious tunnel projects (see case studies below).

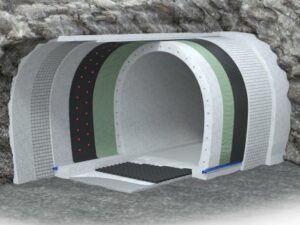

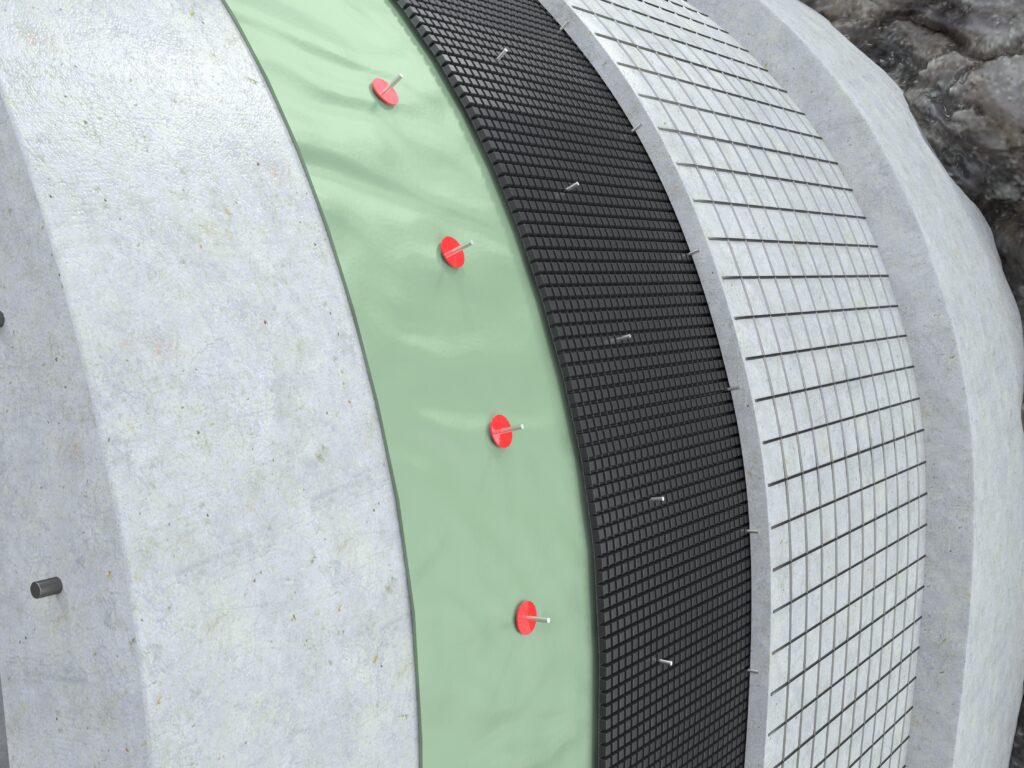

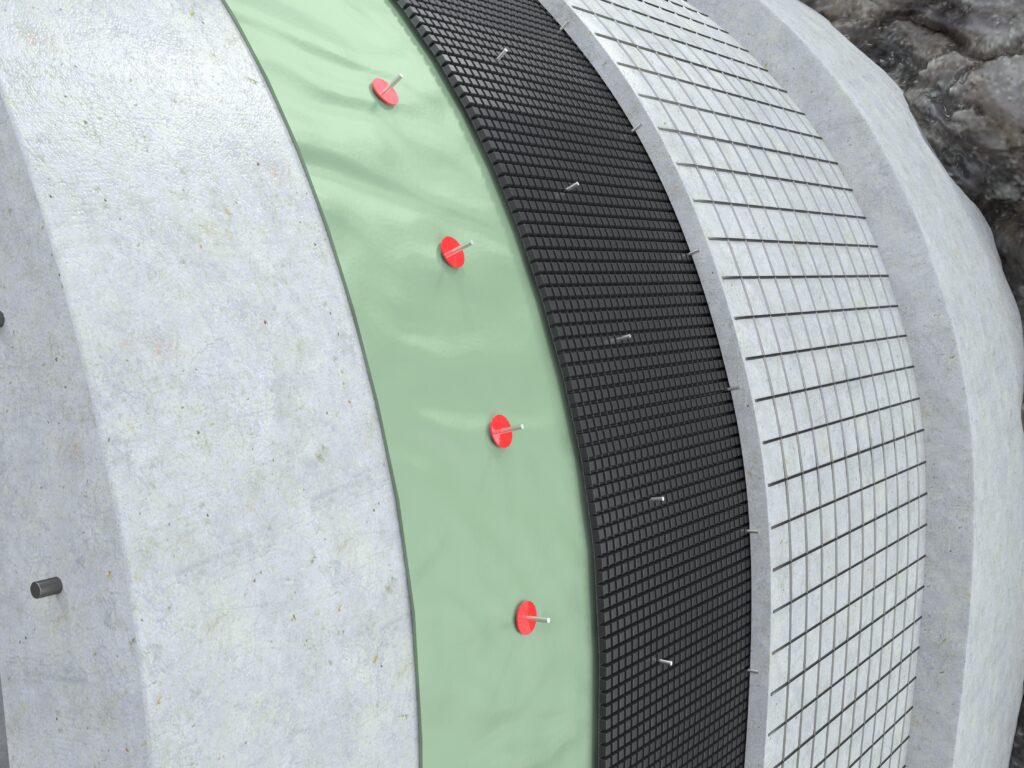

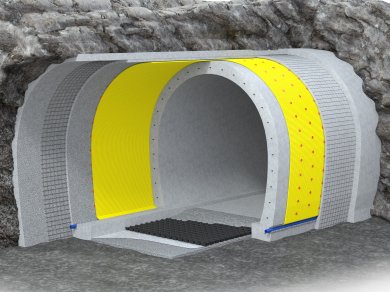

Tunnel Wall Protection & Drainage

Cavidrain® Protector provides a free draining layer to collect infiltration water from behind tunnel linings, as well as providing protection from physical damage. Cavidrain® Protector acts to minimise the build-up of hydrostatic pressure, thus protecting and enhancing the effectiveness of the waterproofing layer.

Cavidrain® Protector Tunnel Wall Combined Drainage & Waterproofing Liner

Cavidrain® Liner is a combined drainage and waterproofing liner that is welded or taped to form an integral waterproof system. Cavidrain® Liner cuspated LLDPE sheets are easily fixed to the smoothed excavated walls with a sealed fixing detail and the system is finished with sprayed concrete. The rebound loss is significantly lower than applying a SCL onto a smooth PVC liner.

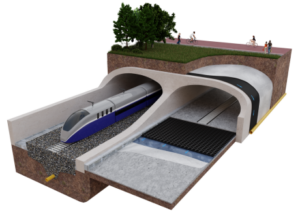

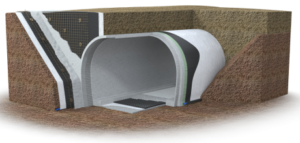

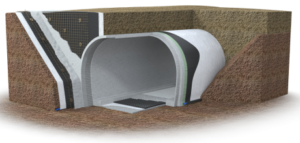

Cut & Cover Tunnel Drainage

ABG Deckdrain is a high performance geocomposite drainage system, providing an effective and environmentally friendly alternative to traditional granular structural drainage on cut and cover tunnels and green tunnels. ABG Deckdrain has a high flow capacity and provides added protection to the external walls of the tunnel.

The HDPE cuspated core of the geocomposite provides a free flowing drainage void allowing water to flow in all directions, unlike linear or pipe systems. The cuspates are designed to support the stiffened filtration geotextile which is thermally bonded to the core. This ensures that the geotextile does not deform into the drainage void under the pressure of the backfill material. Find out more information about flow testing here.

ABG Deckdrain is durable and sufficiently robust to resist the mechanical stresses imposed during installation and then on throughout its design life. The use of ABG Deckdrain eliminates the need for further protection of the waterproofing system. Deckdrain has been creep tested at compressive loads of up to 1,000 kPa to give a design life of 120 years.

ABG Deckdrain geocomposite is used in the construction of green bridges and green tunnels to protect the waterproofing and provide drainage to the structure, which removes the need for bulky porous blocks and the logistical challenge of importing granular fill.

RISQS Verified

ABG are RISQS Verified – (Railway Industry Supplier Qualification Scheme)