Project Description

The Brynglas Tunnel is situated on the M4 Motorway under Brynglas Hill in Newport, South Wales. The 370m twin-bored tunnels were the first tunnels in the British motorway network and are still the only bored tunnels. The tunnels and adjacent M4 motorway at Usk Bridge were originally planned by Newport Corporation in 1959. Work started on the £3m tunnels in 1962. Both structures were complete and open to traffic on 5th May 1967. Almost as soon as the M4 Newport bypass (junctions 24-28) had opened, the traffic levels had grown to such a degree that the road had to be widened to three lanes in each direction. This was finished in 1982 with the exception of the tunnels and Usk Bridge which remained as dual two-lane sections (Junctions 25-26). The Authority approached Capita Symonds Consultancy to design and supervise the reconstruction of this important tunnel on the M4 motorway.

The Challenge

The requirement was to refurbish the tunnel and design a drainage solution that would enable fast installation on this very busy motorway.

The traditional method of using drainage stone was considered outdated, costly and inadequate. A cost saving technique and innovative design was required for the reconstruction of this critical tunnel on the M4 motorway.

A key aim of the design strategy was to minimise the required installation time and enable each section to be completed within the six-hour night time closure window.

The Solution

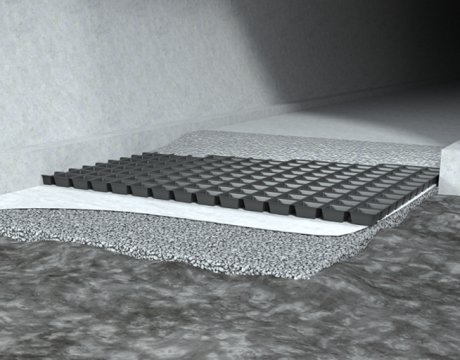

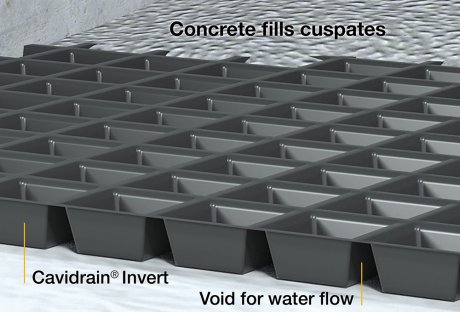

Designer Capita Symonds worked with ABG to develop a geosynthetic solution that would provide adequate drainage, fast installation and reliable long term performance. The Cavidrain Invert 20 drainage layer was specified and installed with 80mm of fast setting screed (10N/mm2 in 3hr), 250mm reinforced concrete slab and 135mm asphalt overlay on top. The concrete filled the Cavidrain geocomposites cuspates to create interconnecting drainage channels, ensuring high flow capacity.

The ABG Service

ABG provided technical advice and design assistance on this tunnelling project. This included a trial installation, site meetings and coordinating time sensitive deliveries with the contractor.

Contact ABG today to discuss your tunnel project and drainage specific requirements and discover how ABG past experience and innovative products can help.