Legacy Way is Brisbane City Council’s award winning 4.6km twin parallel tunnel project that connects the Western Freeway with the Inner City Bypass (ICB). Opened in 2015, Legacy Way halved the peak hour travel time. Transcity was the consortium responsible for the design, construction and operation made up of BMD Constructions and tunnellers Ghella and Acciona Infrastructures.

The Challenge

As with any tunnel project, the waterproofing and drainage of the tunnel invert is important to prevent internal corrosive damage to reinforced concrete floors and avoid uplift pressures on the tunnel structure. In certain places in the tunnel, large flat areas of slab were constructed needing a drainage system with a fall to take water away. Traditionally, a thick granular drainage blanket with additional strip drains and pipes is used. This requires much excavation and the hauling of expensive granular drainage stone along the length of the tunnel in cramped conditions. An additional challenge is that the area geologically is made up of calcareous limestone and iron ore which in solution deposits precipitate on any surface forming a thick, impermeable crust. This would quickly clog any granular drainage system.

The Solution

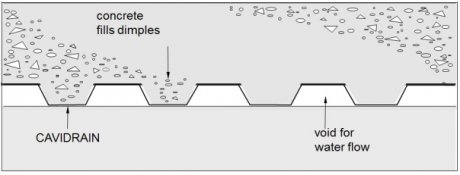

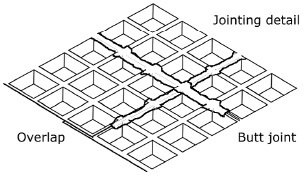

ABG Cavidrain Invert S60 was offered as a multi direction, large void, impermeable drainage system under the whole of the floor area. The high density polyethylene (HDPE) void former is easily jointed or overlapped and sealed to form a waterproof lining to the underside of the slab. Wet concrete completely fills the upturned cups and, when set, transmits load to the base slab leaving large channels in all directions for water flow.

Cavidrain is delivered stacked on pallets for easy transport and laid out in a matrix by hand. This saves on unnecessary extra dig for equivalent drainage stone and pipes which provided considerable savings.

The smooth HDPE surface minimises the attachment of calcium carbonate and iron oxide. Calculations showed the Cavidrain has high redundancy with many flow paths. Maintenance manholes were also provided to allow high pressure jetting. The Cavidrain provided smooth, easily flushable channels for easy maintenance, lengthening the lifespan of the drain many times.

The ABG Service

ABG worked closely with Transcity and provided: Design calculations to prove drainage equivalency, load spread over channels and timed deliveries to suit the site.

Contact ABG today to discuss your project specific requirements and discover how ABG past experience and innovative products can help.