Project Description

Decommissioning of Dounreay is Europe’s largest nuclear site closure project. A key part of the decommissioning was the requirement for a facility in which to dispose and safely store 175,000 m³ of solid, low level waste (LLW) expected to be generated during the clean-out and dismantling of the nuclear reactors. A study was commissioned to identify the best practicable environmental option for the new waste facility.

The Challenge

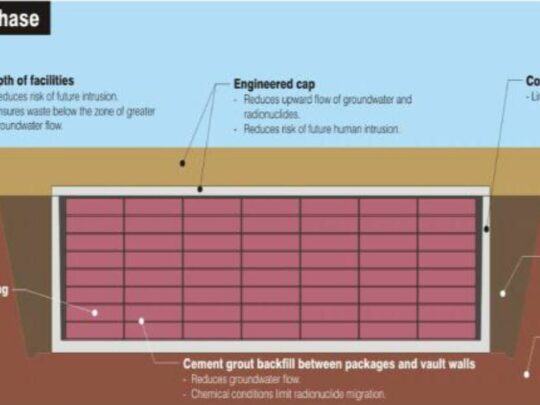

The radioactive material had to be kept safe for 300 years by which time 95% of the radioactivity will have decayed. An on-site facility was preferred because it avoided the need to transport radioactive material on public roads. Many factors were considered to select a location that had no significant risk of coastal erosion or flooding, avoided geological fault zones, did not affect protected species and would not impact on the ground water. Extensive technical studies, an environmental impact assessment (EIA) and site investigation (SI) led to planning permission for an underground facility.

Graham Construction was awarded the contract to design and build two vaults at a cost of £20M. The vaults are 11m deep, 80m long and 50m wide and involved the excavation of 278,212 m³ of rock, 51,073 m³ of subsoil and 31,143m³ of topsoil disposed to landfill on site. The concrete vaults are designed to optimise durability and delay the ingress of groundwater. A total of 7,600m³ of concrete and 1,330 tonnes of reinforcement were used.

The Solution

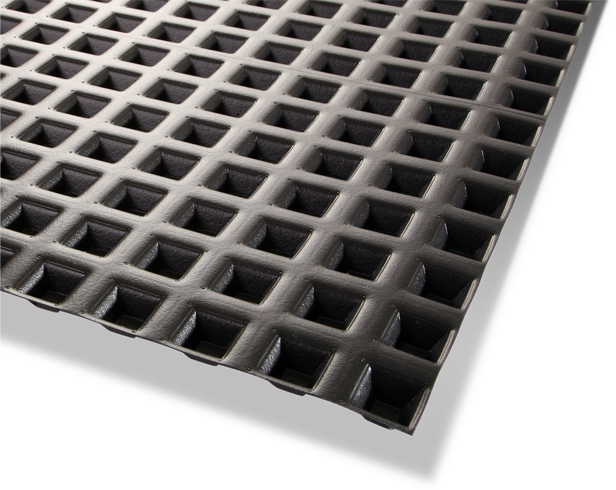

Two features of the design are key to the containment. First, the packaging, backfill and concrete structure restrict groundwater flow through the LLW. The LLW is packed in drums and approx. 200 drums are packed into freight containers, which are then pressure-grouted before moving into the storage vault. Secondly, the concrete alters the chemical conditions such that it binds the radionuclides to the concrete to minimise leaching. The concrete walls, floor slab and roof are 500mm thick and an air gap is maintained externally around them. This is achieved under the concrete floor slab by means of Cavidrain drainage geocomposite. Cavidrain is an HDPE cuspated void former with an impermeable upper surface onto which the concrete slab is cast. The concrete fills the cuspates, which means that the Cavidrain geocomposite becomes as strong as the concrete and transfers the loading to the formation. The voids between the cuspates ensure that air or groundwater can flow safely through Cavidrain in all directions.

The ABG Service

ABG provided technical guidance and manufactured Cavidrain in specific lengths to suit the project.

Contact ABG today to discuss your project specific structural drainage requirements and discover how ABG past experience and innovative products can help.