Project Description

Towndoor owns and manages the site of the former David Brown Tractors Group factory in West Yorkshire. Once the UK’s largest tractor factory, the site is now a thriving collection of industrial units. The present buildings date from the 1940s but there are also remnants of the earlier Brooks silk mills which had two large concrete lined water reservoirs on the site.

The Challenge

Towndoor required additional hard standing for car parking immediately adjacent to a factory unit. There was space available but the existing ground was 1.5m – 2.0m below road level and in-filling was required. The factory wall was incapable of receiving lateral loads if the void was filled, so an independent retaining structure was required. A concrete retaining wall would be prohibitively expensive. Since the area was intended for parking, a vehicle barrier was also required to protect the factory wall from possible vehicle impact.

The Solution

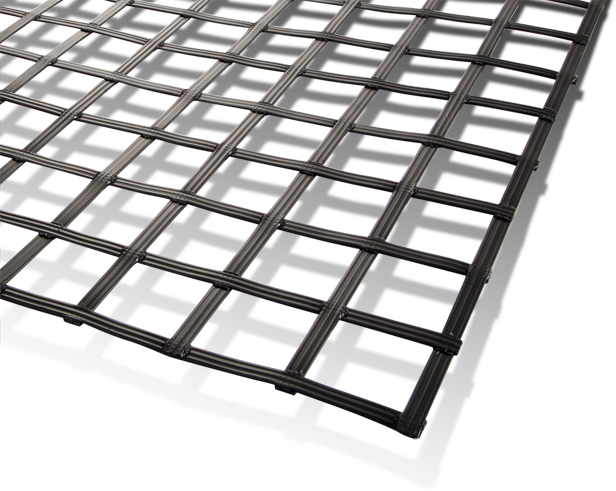

ABG suggested the use of reinforced fill which would be self-supporting and therefore not impose any loads onto the factory wall. The crushed stone fill was reinforced with Trigrid EX30 biaxial geogrid using the wrap-around method of facing. It was essential that a small space remained between the face of the reinforced fill and the factory wall.

The factory wall was used to provide temporary lateral restraint to a “climbing” timber form which maintained the void between the reinforced fill and the factory wall as each layer was constructed. The reinforced fill comprised geogrid at 500mm spacing and a graded crushed stone.

Trigrid EX30 geogrid is a high performance geogrid comprising polyester tensile elements in a robust polypropylene sheath. The polyester core provides creep-resistant long-term strength, whilst the polypropylene sheath provides protection from installation damage.

The ABG Service

ABG was able to provide a solution that was completed in a month and a half prior to Christmas, in weather conditions that may have prohibited conventional in-situ concrete work.

Contact ABG today to discuss your project specific reinforcement or stabilisation requirements and discover how ABG’s past experience and innovative products can help.