Project Description

The Alto Velocidad Española (AVE) is Europe’s largest high speed rail network. The ambitious construction project was undertaken to improve connections between all of Spain’s major cities, reducing commute time and contributing to socio-economic regeneration. The new Sevilla to Cádiz railway line would be an extension of the Madrid to Sevilla route, connecting Cádiz to Jerez Airport and crossing areas of outstanding natural beauty.

The Challenge

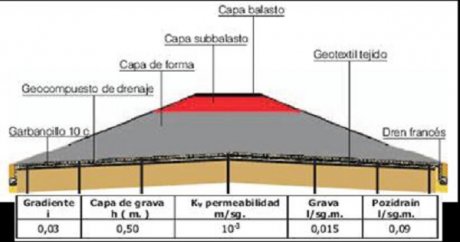

The new route would traverse an area of Bahia del Sur (Cádiz) where an embankment would be constructed to accommodate the railway line. Ground investigations identified soft, wet soils which would be unsuitable for construction without remediation to improve stability. This would traditionally be addressed through a combination of vertical wick drains and a granular drainage blanket to direct the water horizontally to French drains adjacent to the embankment. However this method required the use of large quantities of costly imported granular material, which would also prove slow to install. These considerations led the designer to consider the use of a drainage geocomposite to act as a horizontal drainage blanket, a methodology which had proved successful in other infrastructure works on soft ground.

The Solution

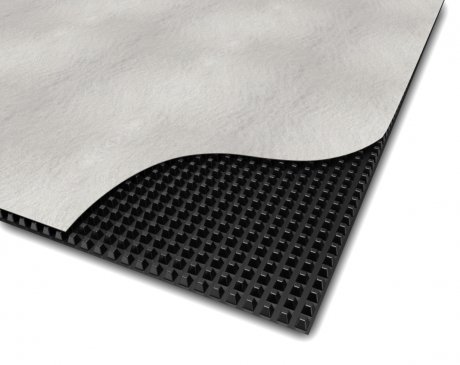

The contractor Terratest approached ABG to assist in the redesign utilising Pozidrain drainage geocomposite comprising a high-strength drainage core thermally bonded to a filtration geotextile. ABG calculated the equivalent in-plane flow of the granular material using Darcy’s Law, and proposed a suitable grade of Pozidrain to manage the expected water flows. The required in-plane flow capacity was tested to EN ISO 12958 using soft foam platens to simulate soil overburden. Design calculations, which accounted for the weight of the embankment and the traffic loads, indicated a long-term pressure at the base of the embankment in excess of 55 kPa. Pozidrain 4SK500/NW8 was chosen to provide a 9.0 factor of safety. Pozidrain was installed by the contractor in a fraction of the time required for the original granular design, meeting tight project timescales and providing a significant cost saving.

ABG Pozidrain

The ABG Service

ABG worked closely with Terratest to provide full design support, comparisons, costing and supply.